Chemical Decapsulator Systems for ICs

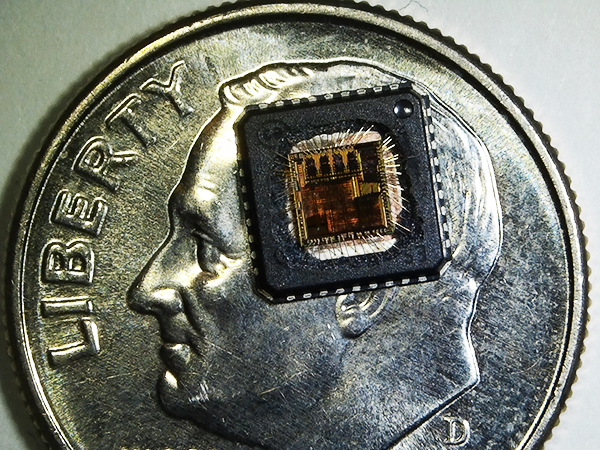

RKD Engineering develops a series of acid decapsulation tools which use the jet etching process. Our automated IC decapsulation systems allow an individual to safely open a wide range of packaged semiconductor devices.

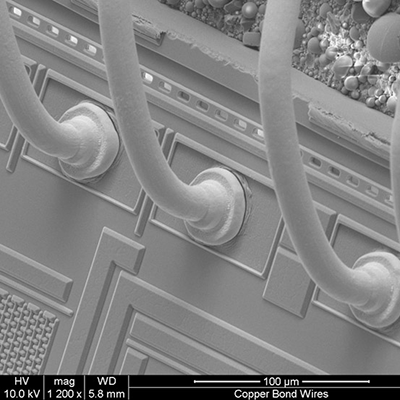

We offer the most reliable failure analysis and sample preparation solutions for integrated circuits. Our systems expose delicate silicon die surfaces and fragile bond wires made of Gold, Aluminum, Copper, and now Silver. RKD Engineering also provides precision mechanical precavition tools.

RKD Engineering continues to develop products for the evolving semiconductor industry to make sample preparation easier, faster, and more reliable.

Upcoming Event

The complete RKD Engineering product line will be available for demonstration at the ISTFA 2019 Symposium at the Oregon Convention Center in Portland, Oregon! The RKD Engineering team will be on site to showcase our suite of failure analysis tools, along with product information and demonstrations.

ISTFA - Portland 2019

8/07/19We will be exhibiting two new products for failure analysis at the 2019 ISTFA conference in Portland, Oregon. We will be featuring our Elite Etch systems as well, the Gold Standard of jet etching decapsulation.

Visit our booth for exclusive deals on all of our systems. We are booth number 612, and will be exhibiting November 12th and 13th.ISTFA - Phoenix 2018

11/02/18The complete RKD Engineering product line was available for demonstration at ISTFA 2018 at the Phoenix Convention Center in Phoenix, Arizona! The RKD Engineering team was happy to showcase our suite of failure analysis tools.

We look forward to your continued business in the year 2019!Semicon Taiwan 2018

7/26/18Shining Technology Corporation will be representing RKD Engineering at the 2018 Semicon Taiwan exhibition. The Mega Etch with ESD mitigation will be featured as well as the I53 injector, used to safely expose integrated circuits with silver internal wires. We hope to see you there!

Our products will be on display from September 5th to September 7th in booth K2188 on the 1st FloorIPFA 2018 - Singapore

6/29/18Radiant Advanced Devices will be showcasing RKD Engineering products at the International Symposium on the Physical and Failure Analysis of Integrated Circuits. Please join us for a demonstration of the Elite Etch series and more.

We will be attending from July 16th to July 19th in booth B23Semicon Southeast Asia 2018

5/11/18RKD Engineering would like to thank Shining Technology and all the guests who visited our booth at Semicon SEA 2018. We look forward to hearing from you in the future!

Semicon SEA 2018Website Update

5/8/18RKD Engineering is proud to unveil a new and updated website! Products and Services are available to view and order.

Check back soon for more updates.ISTFA 2017

11/9/17This year at the ISTFA 2017 we were glad to meet so many engineers interested in our booth. See you all next year at Phoenix, Arizona!

Please feel free to contact us with any remaining questions you have.I53 Injector

6/6/17With a shortage of precious metals, manufacturers are experimenting with new silver bond wire solutions. RKD is the only manufacturer equipped to expose silver wire technology without causing harm to the IC.

Request a quote for the I53 Injector today.The Mega Etch

10/2/16Do you need the space to decapsulate a chip on a large surface PCB? Do you want to power up your semiconductor even after it has been decapsulated? Check out our RKD Engineering Mega Etch.

Available immediately on our product page.The Nano Mill II

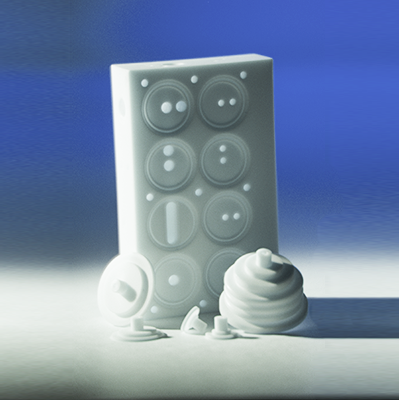

2/5/16The Nano Mill II gives the option to custom make gaskets for etcher surface contact. In addition, the Nano Mill II can precavitate packages to minimize etching times and fluid usage.

Available immediately on our product page.

RKD Engineering

RKD Engineering specializes in acid decapsulation for semiconductor packages. With over 25 years of experience in the failure analysis and semiconductor industry, our mission is to provide the highest quality products for semiconductor failure analysis by using a patented acid delivery system.

Product Features:

• The most reliable IC failure analysis and sample preparation systems.

• Easy to use counterfeit detection systems and equipment packages.

• Integrated chemical resistant fluid handling systems.

Applications

Our systems are used extensively in multiple industries today. Some common applications for our products include:

• Jet etching for liquid penetration inspection

• Encapsulant removal for bond wire analysis

• SEM metallography through device exposure

• Anti-corrosion sample preparation for nondestructive examination

• Protection of silver wire bonds in integrated circuits

• Heat sink removal

Counterfeit Detection

Our solutions can be used to understand your supplier better. By using wet etch decapsulation, you can be sure that the semiconductor products you pay for are the products you receive.

Considerations:

• Are the best quality materials used in the package?

• Does the manufacturer identifier appear on the silicon die?

• Has the semiconductor been stored or shipped safely?

All these questions can be answered using an RKD Engineering decapsulation system.

Fluid Handling and Pumping

RKD Engineering designs and manufactures positive displacement diaphragm metering pumps and fluid handling systems. Our pumps have PTFE wetted parts and are pneumatically actuated to totally isolate the fluid path to the package.

Our pumps are used in our own semiconductor failure analysis products to safely deliver fuming nitric acids, sulfuric acids, and organic solvents. The scalability of the RKD Engineering pump design allows integration into various fluid control systems into a single autonomous assembly.

Our chemical fluid pumps are available for custom scientific and industrial applications.